熱門關鍵詞: 臺灣圓臺磨床 磨床生產廠家 精密數控磨床 雙工位立軸圓臺平面磨床

數控平面(mian)磨床(chuang)工作臺面(mian)使用和保養事項

數(shu)控(kong)平面(mian)磨床在使(shi)用(yong)完畢(bi)切(qie)斷電源(yuan)后,由于余(yu)磁的(de)作用(yong),加工(gong)(gong)的(de)工(gong)(gong)件(jian)不易(yi)從(cong)工(gong)(gong)作臺面(mian)上取下,所(suo)以需要把控(kong)制磁力的(de)開關(guan)轉換到退磁的(de)位(wei)置,多次(ci)反復直到使(shi)得余(yu)磁完全消失,然后取下工(gong)(gong)件(jian);

對于(yu)大(da)工(gong)件(jian),當其與工(gong)作臺(tai)面接(jie)觸面積(ji)較大(da)時,結束磨削后,由于(yu)余磁(ci)以(yi)及光滑(hua)表面的(de)吸附力,使得工(gong)件(jian)取出比較困難,這個時候,我們不可以(yi)強硬(ying)拖拽,可以(yi)使用木棒(bang)(bang)、銅棒(bang)(bang)或(huo)者合適的(de)工(gong)具(ju)輕輕將(jiang)工(gong)件(jian)扳動(dong)后再慢(man)慢(man)取下,避免劃傷(shang)工(gong)作臺(tai)面或(huo)者劃傷(shang)工(gong)件(jian);

我們在磨床上裝夾工(gong)(gong)(gong)件(jian)時,要確保工(gong)(gong)(gong)件(jian)放置(zhi)的位置(zhi)覆蓋(gai)的絕磁層條數盡可能多,保證充分利用磁力,加固工(gong)(gong)(gong)件(jian),此(ci)外,工(gong)(gong)(gong)件(jian)盡量放置(zhi)于工(gong)(gong)(gong)作臺面中央(yang),大工(gong)(gong)(gong)件(jian)還需要在其周圍放上擋塊放置(zhi)移(yi)動(dong);

平面磨床(chuang)工(gong)作(zuo)臺面要(yao)保持平整光滑,定期修修磨,有(you)垃圾(ji)時需要(yao)用油石(shi)或者紗布拋光;

數(shu)控平面(mian)磨(mo)床結束工作后,需(xu)要將(jiang)工作臺(tai)面(mian)擦(ca)(ca)拭(shi)(shi)干(gan)凈,臺(tai)面(mian)不(bu)(bu)得出現嚴重磕碰,避免破壞其精度,長時(shi)(shi)間不(bu)(bu)使(shi)用數(shu)控平面(mian)磨(mo)床時(shi)(shi),我(wo)們要將(jiang)工作臺(tai)面(mian)擦(ca)(ca)拭(shi)(shi)干(gan)凈并涂上防銹(xiu)油;

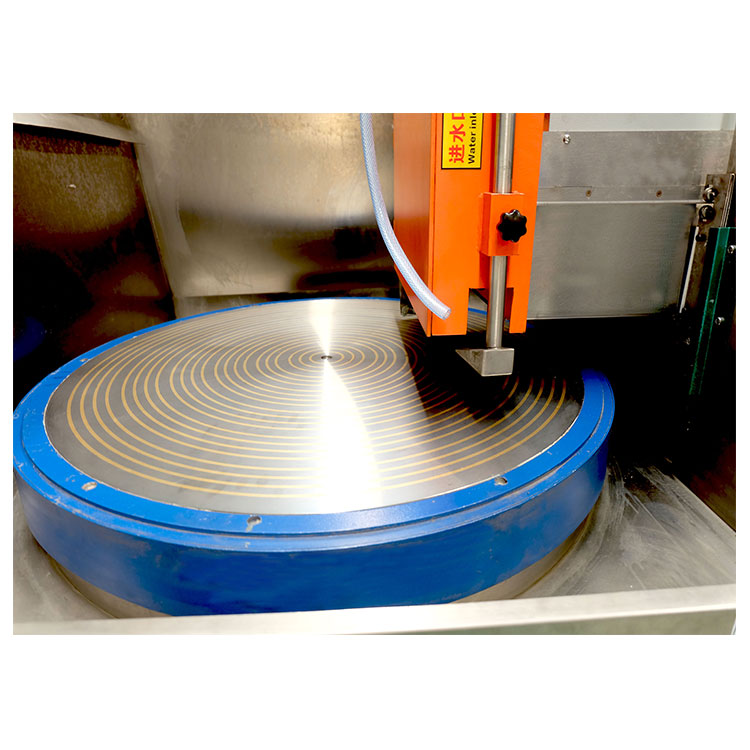

SKM7380數控(kong)臥軸圓臺平面(mian)磨(mo)床工作臺面(mian)

400電話

微信客服